Hup for Homeowners in Devon and Cornwall

Hup is a building regulations approved walling system that is a bit of a game changer for our industry, developed to assist homeowners in achieving dream extension living results.

Here is a taster of this new product.

Welcome to the hup! Specification Guide

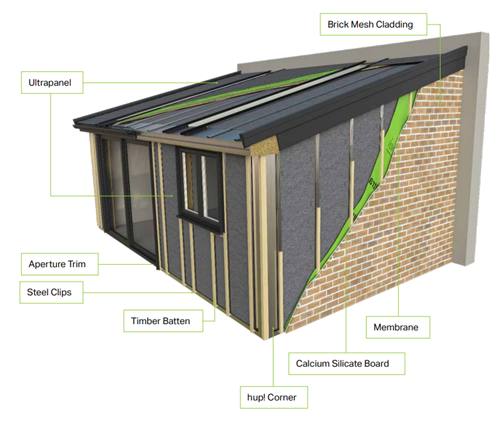

Using the latest Ultrapanel technology and pre-manufactured to the required specifications, the hup!

system is quick to build, hassle free and requires minimal cutting or drilling on site. The hup! system has

been designed to be installed by trained conservatory fitters or builders and is fully compliant with the

latest Building Regulations with a U-Value of 0.17W/m²K for the walls, 0.15 W/m²K for solid roofs, and

1.4W/m²K for glazed roofs. The product is available with various shades of unique hup! Brick Mesh finishes

to give the appearance of a traditional brick wall and is compatible with any other wall finishes available on

the market.

Below is a typical Tiled Roof lean-to extension.

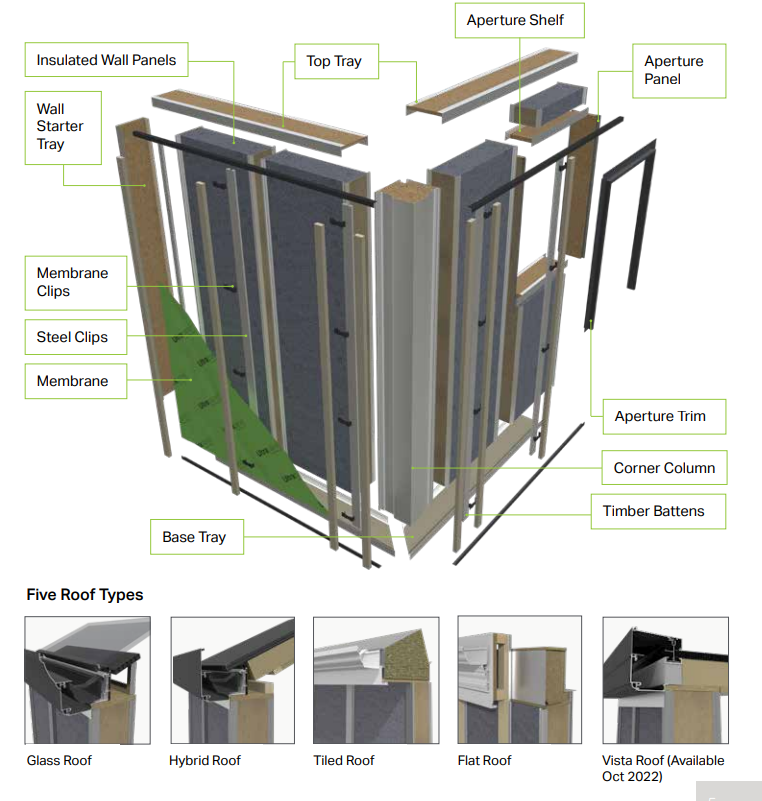

The hup! building system is designed to be used with any of the five Ultraframe roofing systems

hup! walls, when combined with the choice of one of five different roofing systems, deliver a lightweight

yet robust structural solution which can be built and made watertight in a fraction of the time it takes to

build the equivalent structure using standard construction methods.

Wall Panel Components

Five Times More Energy Efficient – Easy Building Regulations

• Five times more energy efficient than the average UK home.

• Components compliant with Part L June 2022 Building Regulations.

• Solid roofs with U-Values less than 0.15 W/m²K for England and 0.13W/m²K

in Scotland.

• Walls with a U-Value of 0.17 W/m²K, exceeding Building Regulations.

Less Trades – Easy Project Management

• No bricks required – range of authentic Brick Mesh wall finishes.

• Designed to be fitted by one conservatory team.

• Comprehensive fitting team training provided.

• Design, specify and price in one easy U-Design order.

Five Times Faster to Build – Collect Cash Quicker

• 100% pre-fabrication, no cutting required on site.

• Rapid wall and roof connections.

• 10m2 of wall built in minutes.

• Can be built in most weather conditions unlike brick.

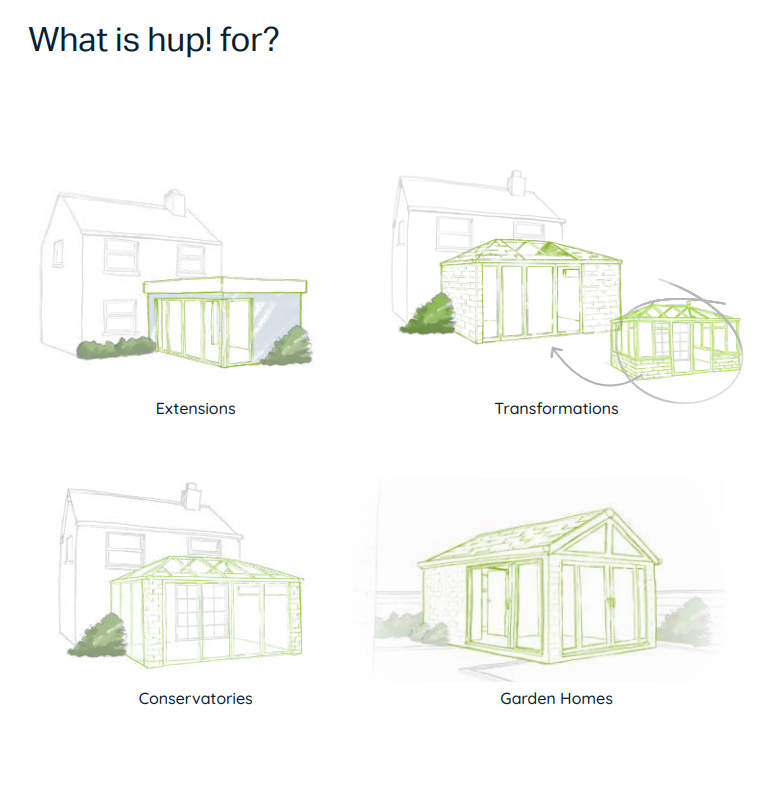

Ultimate Design Flexibility – Convert More Sales

• Choose from five Ultraframe roofs.

• Compatible with any wall finishes.

• Configurable to any window and door layout.

• Perfect for extensions, conservatories, transformations, and garden homes.

Engineered by Ultraframe – High Quality Finish

• BBA approved Ultrapanel technology from a BBA approved factory.

• Designed to accommodate on site tolerances.

• Precision engineered for a consistent high quality finish.

• No cold bridging.

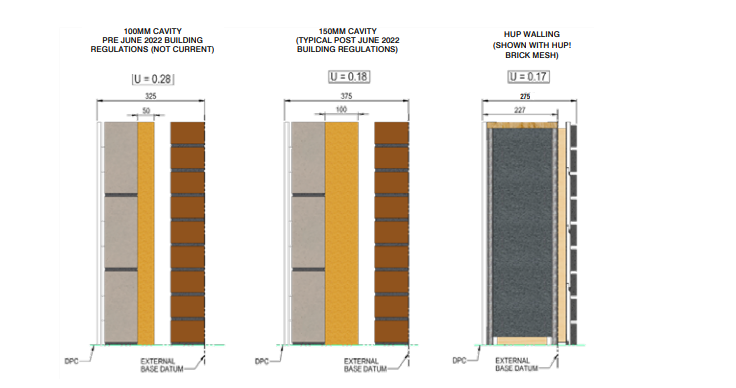

Wall Thickness and U-Values

Building Regulations requirements for walls

New Building Regulations specify that walls should have a U-Value of 0.18W/m²K. The outgoing regulation

specified a value of 0.28W/m²K. To achieve this new value in traditional brick and block construction, the

width of the cavity wall will increase from 300mm to 350mm. This size is increased further with the addition

of dot and dab plasterboard on the inside (325mm and 375mm respectively). The hup! wall system

achieves a U-Value of 0.17W/m²K and only has a width of 227mm, however with the addition of both the

external Brick Mesh finish and plasterboard on the internal face, has an overall thickness of 275mm. This

27% reduction in width over the new brick requirement results in additional internal floor space.

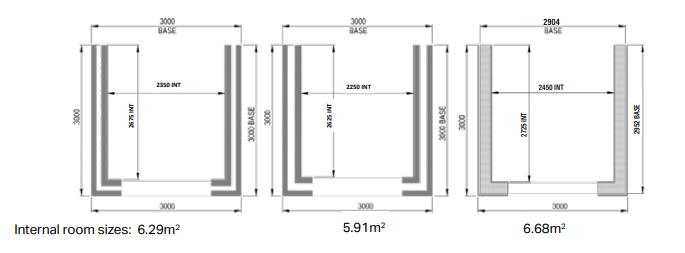

Footprints (Internal & External)

Below is a comparison between typical builds using traditional brick methods above and hup!. The

example shown is for a 3000mm x 3000mm external wall. Assuming that the wall finish is brick mesh finish

the external base of hup! is 2904mm wide by 2952mm projection, giving an overall external brick size of

3000mm x 3000mm.

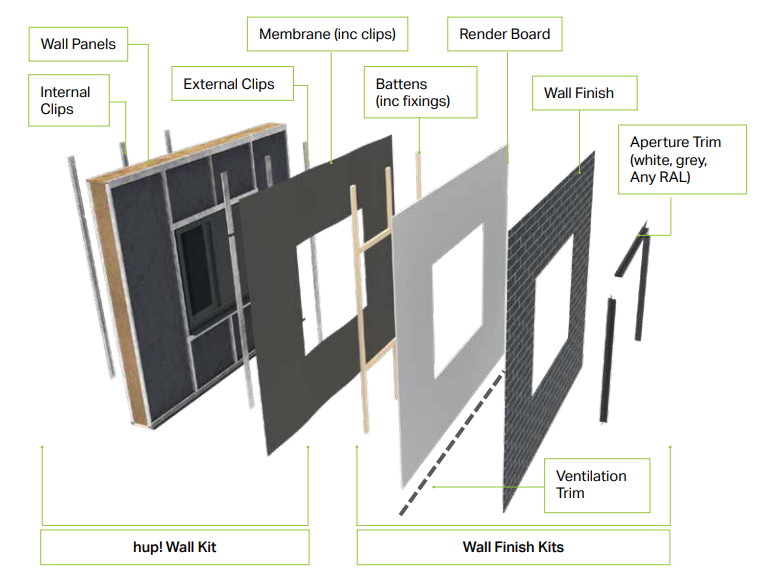

What’s Supplied?

The hup! wall kit consists of everything you need to get your hup! building watertight including Ultrapanels,

Ultrapanel clips, wall and base trays, membrane and clips to fix the membrane to the Ultrapanel clips.

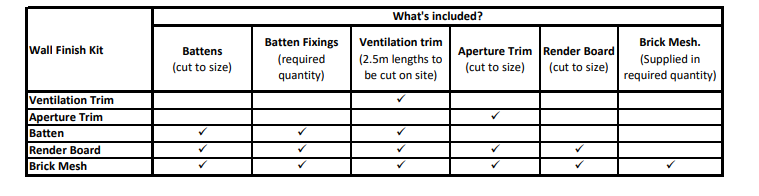

It’s up to you to decide how you want to finish your wall and we can provide you with all of the elements

including our Brick Mesh or, if you want to provide your own wall finishes, we can provide other elements

to help you finish your wall as required. Choose from one of the wall kits in the table below which shows

you what is included in each kit.

Wall Finish Kits

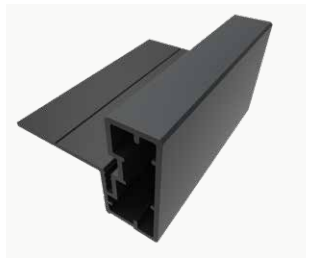

Ventilation Trim

To comply with Building Regulations, hup! has a drained and ventilated air gap behind the external

calcium silicate board. The system allows for 10mm continuous ventilation.

To prevent vermin or insect ingress and other debris, the wall finish is supplied with a ventilation

trim which has 3mm slots incorporated into the profile along its length. This profile runs around the

perimeter of the build at the top and bottom of the walling.

The ventilation trim can be ordered separately if using your own wall finishes or it is supplied with the batten, render board, or Brick Mesh wall kits. Enough 2.5m lengths are supplied to run along both the top and the bottom of the hup! build.

Aperture Trim

The aperture trim accommodates wall finishes up to 25mm which is enough for most wall finishes. If brick slips are used with the aperture trim, the edge of the brick will be visible.

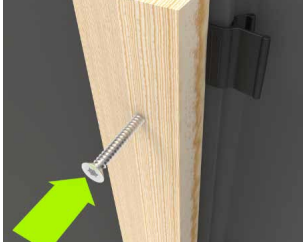

Battens and Batten Fixings

The battens supplied are 25 x 50mm and fit to the Ultrapanel clips with a specialist self drilling winged screw designed to penetrate and fix securely to the timber and the steel clips.

Wall Finishes – Render Board

Calcium silicate board fixed to timber batten

Calcium silicate board is manufactured from a mixture of Portland cement, fine silica, special cellulose

fibres and selected fillers to impart durability, toughness, fire and moisture resistance.

Calcium silicate panels will not degrade with time and within normal applications. Calcium silicate board

will not rot or support fungal growth and is unaffected by sunlight or steam.

Calcium silicate sheet is specially designed for applications which require impact resistance, fireproof (A1

Class), waterproof, sound absorption and heat isolation. These products are suitable in a high humidity

environment.

The calcium silicate boards are 12mm in thickness and are pre cut to suit the walling layout of the hup!

extension. Each board is marked with its location which coordinates with the provided location plan.

The boards are screwed directly to the timber battens using the provided square drive self drilling screws.

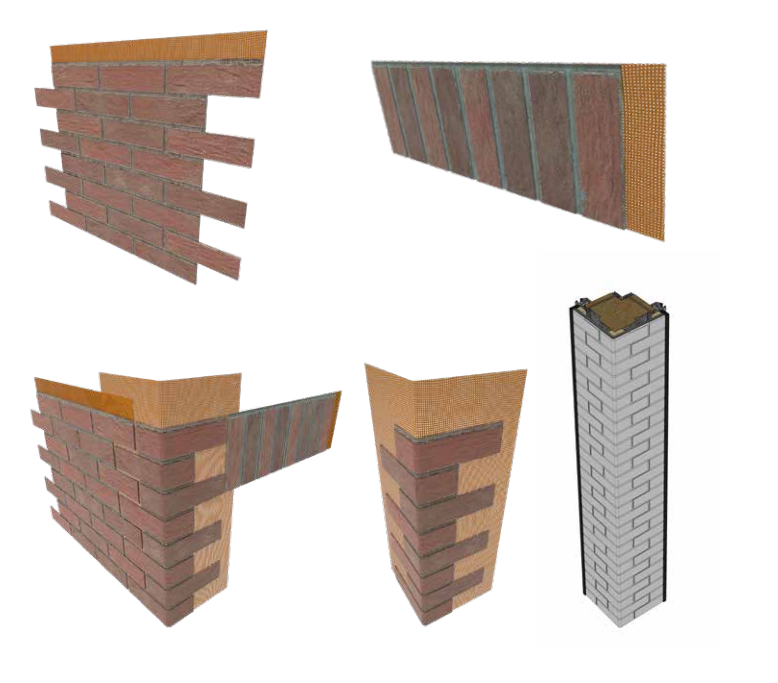

Wall Finishes – Brick Mesh

The Brick Mesh wall finish comes pre-pointed on sheets which are x 8 courses high to match the x

3 courses wide and are applied to the surface of the calcium silicate board using a mortar coloured

adhesive. There are 5 component elements to the mesh wall finish. A ‘map’ of where each brick mesh

panel should be applied will be provided as part of the on site paperwork.

• Brick Mesh sheet

• Corner (1 brick)

• Soldier course for over apertures (optional)

• Mesh jointing

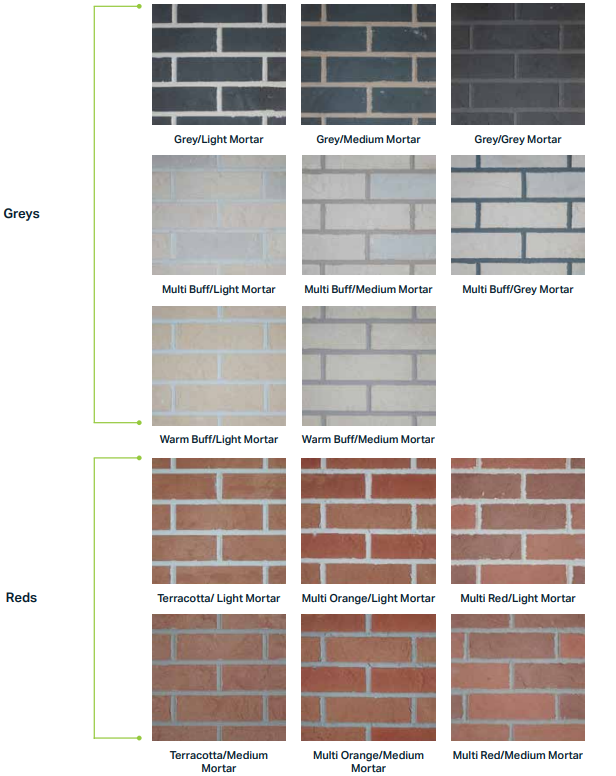

Brick Mesh Options

The hup! Brick Mesh is available in a range of brick colour and mortar colour combinations. All

bricks are 215mm x 65mm with a 10mm mortar gap.

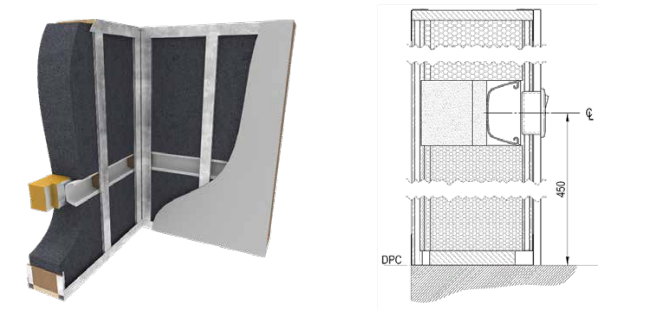

Wiring Details

Cable Management Panels

A cable management panel option is available for running cables around the perimeter of the build. It is

supplied on every panel if this option is selected

• The channel is set at 450mm above the DPC level and allows holes to be drilled between panels

through the hardboard and cables fed through.

• The channel is deep enough to cater for socket back boxes.

• If cables need to be run up the wall, or around apertures, the cable must be sheathed in a flexible

conduit to avoid contact between the cable and the EPS.

• All electrics must be carried out by a certified and qualified electrician.

Tiled Roof

The hup! Tiled Roof is also known as Ultraroof and does not need a tie bar like other lightweight Tiled Roof

systems. Available with a choice of full length glazing panels in a range of high performance glass or conventional Velux windows, the roof can accommodate door spans of up to 4m with no need for extra structural support.

Ultraroof is available with 3 shades of lightweight tiles or can also be used with slate or concrete tiles too.

The hup! Tiled Roof is available in lean-to, hipped lean-to, gable, Georgian, double hipped Georgian,

L-shape and T-shape with a maximum width of 6780mm and projection of 5000mm.

Also for use with LivinRoof, Classic Conservatory, Ultrasky Orangery, and UltraFlat roof

Frequently Asked Questions

Is Planning Permission required?

Check with your Local Authority and the Planning Portal.

Is Building Control approval required?

Check with your Local Authority and the Planning Portal.

What if my extension is close to the boundary (Fire)?

Within 1 metre of the boundary, the hup! wall is required to be fire rated to 30 minutes. The hup! walls have been tested using the calcium silicate board to achieve the required 30 minutes. If specifying your own cladding the relevant fire testing certification will be required for Building Control.

What if my extension is close to the boundary (access)?

If the hup! extension is close to a boundary, either allow enough access between the side wall and the boundary to enable fitting and cladding, or consult with the neighbouring property to allow access during this stage of installation.

How secure is hup! ?

If specifying the hup! Brick Mesh, brick slips, or a rendered finish, the external face of the walls are lined with calcium silicate board beneath the external cladding. This creates a robust external barrier which is incredibly difficult to penetrate. Windows and doors are secured to aperture panels which carry 25mm OSB to ensure fixings are robust.

Why is the trunking horizontal not vertical?

The horizontal trunking is run at a set height of 450mm above floor level to cater for sockets, giving space for back boxes. The main benefit of the trunking is to enable the cables to easily be run across the wall behind the steel clips without the requirement to batten out the inside of the wall, as a hole can be made in the hardboard panel sides to pass the cable between panels. Cabling however can be run vertically in conduit to avoid contact with the EPS.

Can the trunking be at a specified level?

Electrical cables and piping can be ran together provided that they are separated by a 25mm gap. Alternatively the cabling can run around the perimeter of the eaves and dropped down the panel in conduit.

How do we prevent the heat from a radiator affecting the wiring?

The trunking is for electrical cables or network cables only. Electrical cables and piping should not be run together in the trunking. Any pipework should run behind skirting as shown in the Specification Guide in rebated skirting boards. The cabling should not be directly affected by heat from radiators as it will be separated by plasterboard as it would with a stud or block wall.

To what extent do hup! walls let in noise from outside?

The makeup of the hup! wall includes a combination of material densities resulting in excellent sound absorption.

Devon and Cornwall homeowners, if you want to extend your home with a single storey extension or are looking to convert your existing conservatory into an all year round livable room contact us for a chat on 01752 841008 to see how the Hup system can work for you.

Make us 1 of your 3 Quotes and find out why Realistic Home Improvements are so highly recommended.